Polyurethane Foam Jacking Effective Concrete Repair

What is Polyurethane Foam Jacking?

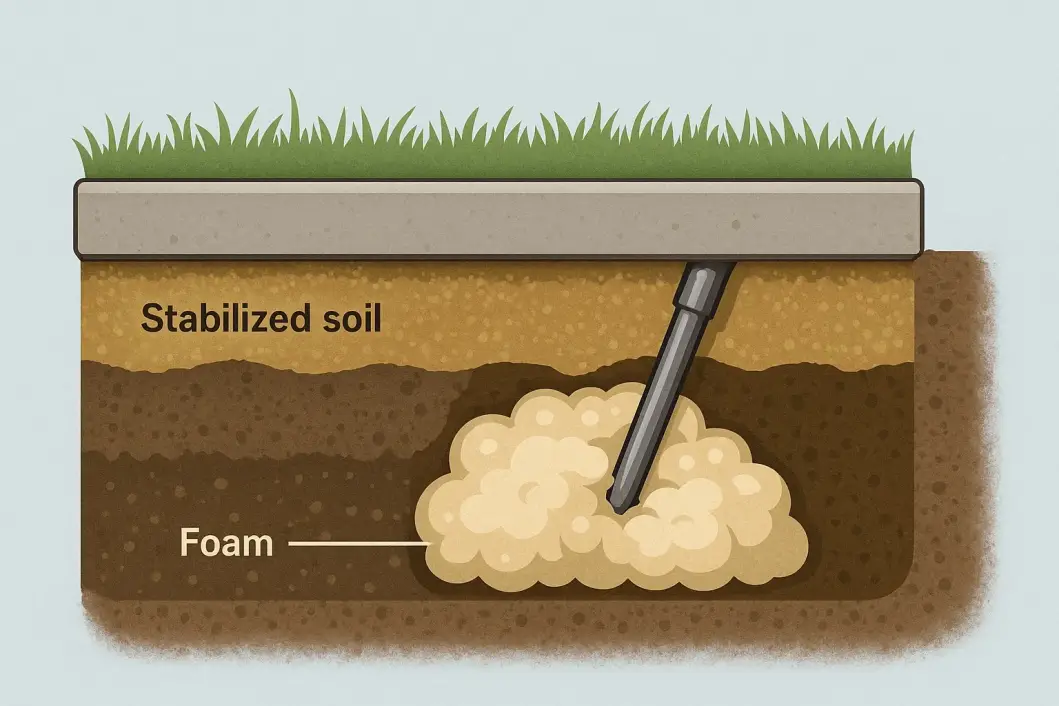

Polyurethane foam jacking involves injecting a liquid polyurethane mixture into small, 5/8-inch holes drilled into the affected concrete slab. Once injected, the polyurethane expands, filling voids and stabilizing loose soil underneath. As it hardens, the foam exerts enough pressure to lift the slab back to its original position. This process not only levels the concrete but also ensures long-term durability by reinforcing the underlying soil.

How Polyurethane Foam Jacking Works

Polyurethane foam jacking is an innovative technique used to restore sunken or uneven concrete surfaces. It provides a permanent solution by stabilizing the soil underneath and lifting the concrete to its original position.

Benefits of Polyurethane Foam Jacking

Minimal Disruption

One of the standout advantages of polyurethane foam jacking is its minimally invasive nature. Unlike traditional methods that require extensive excavation, this technique preserves the surrounding area, leaving your property intact and clean. The small holes in the slab are filled with grout for a smooth finish.

Fast and Efficient

Polyurethane foam cures quickly, typically reaching 95% of its strength within 20 minutes. This rapid curing process means you can resume using the repaired area shortly after the procedure, minimizing downtime.

Cost-Effective Solution

Compared to replacing an entire concrete slab, polyurethane foam jacking is significantly more affordable. It provides a durable and reliable repair without the hefty costs associated with demolition and reconstruction.

Environmentally Friendly

The materials used in polyurethane foam jacking are eco-friendly and designed to last. This method reduces waste by preserving existing concrete structures and minimizing the need for new materials.

Applications of Polyurethane Foam Jacking

This versatile technique can be applied in various scenarios, including:

Patio Leveling

Restore sunken patios to their original level without disturbing landscaping.

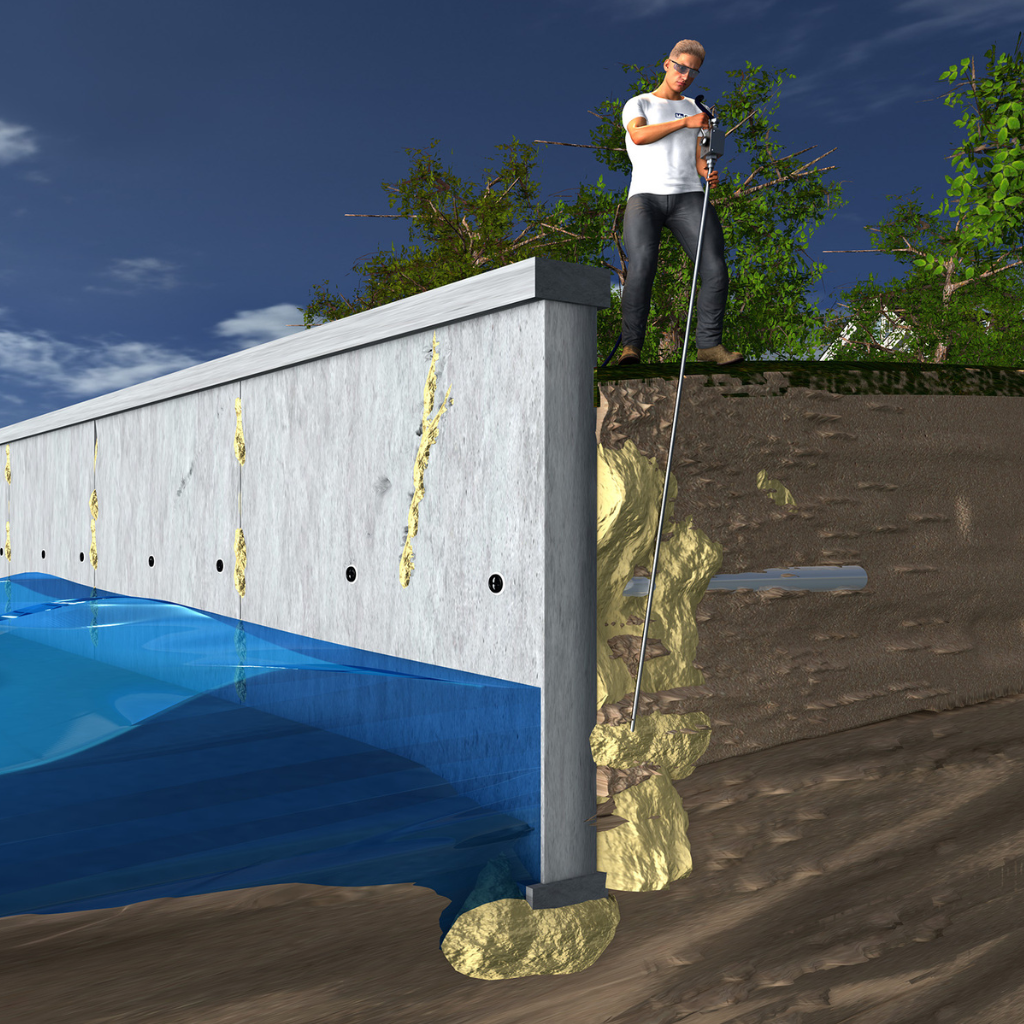

Pool Deck Leveling

Eliminate trip hazards around your pool area by lifting uneven concrete slabs.

Driveway Repair

Address sunken or cracked driveways to ensure a smooth and safe surface.

Sidewalk Leveling

Fix uneven sidewalks to prevent accidents and comply with easy access standards.

Foundation Stabilization

Reinforce the stability of building foundations affected by soil erosion or settling.

The Process: Step-by-Step Guide

1. Assessment

A professional contractor begins by evaluating the affected area to determine the extent of damage and the underlying causes. This step uses the right amount of polyurethane.

2. Drilling

Small, precise holes are drilled into the concrete slab to access the voids beneath. We strategically place the holes to evenly distribute the polyurethane foam.

3. Injection

The polyurethane foam is injected into the drilled holes. As the foam expands, it fills the voids, stabilizes the soil, and lifts the slab back to its original position.

4. Finishing

Once the slab is level, the drilled holes are sealed with a grout mixture, leaving a clean and polished surface.

5. Final Inspection

The contractor performs a thorough inspection to ensure the repair is complete and the slab is stable and level.

Common Issues Addressed by Polyurethane Foam Jacking

Void Formation

Caused by soil erosion or water infiltration.

Uneven Concrete

Resulting from soil settling or improper installation.

Trip Hazards

Uneven surfaces that pose safety risks.

Water Pooling

Low areas on concrete surfaces that collect water, leading to damage over time.

Why Choose Polyurethane Foam Jacking?

Long-Term Durability

The high-density polyurethane used is strong and helps keep the ground stable, providing a long-lasting repair.

Flexibility

This method is suitable for various types of concrete surfaces, from residential patios to commercial foundations.

Cost Savings

By opting for polyurethane foam jacking, property owners can save up to 75% compared to the cost of slab replacement.

Professional Expertise

With the guidance of experienced contractors, you can achieve precise and reliable results tailored to your specific needs.

Additional Benefits of Polyurethane Foam Jacking

Reduced Carbon Footprint

By repairing existing structures rather than replacing them, foam jacking helps reduce the carbon footprint associated with manufacturing and transporting new materials.

Improved Aesthetics

Sunken or uneven concrete can detract from the appearance of your property. Restoring the level of your concrete surfaces enhances curb appeal and overall aesthetics.

Increased Safety

Fixing trip hazards and uneven surfaces lowers the risk of accidents, making your space safer for everyone.

Enhanced Property Value

Level concrete surfaces improve your property’s value, making it more attractive to buyers or tenants.

How to Get Started

If you’re dealing with uneven or sunken concrete, contact Slab Fix today for a free consultation. Our team of experts will assess your situation and provide a tailored solution using polyurethane foam jacking. Call us now to restore the safety, functionality, and appearance of your concrete surfaces.

Frequently Asked Questions

Q: How long does the process take?

Most projects are completed within a few hours, depending on the size and complexity of the repair.

Q: Is polyurethane foam safe?

Yes, the materials used are non-toxic and environmentally friendly.

Q: Can this method be used for large commercial projects?

Absolutely! Polyurethane foam jacking is scalable and effective for both residential and commercial applications.

Q: How soon can I use the repaired area?

You can typically use the repaired surface within 30 minutes after the procedure is complete.

Q: Will the holes in the concrete be noticeable?

We fill the small 5/8-inch holes with grout, making them barely noticeable and keeping the surface looking good.

Contact Slab Fix for Concrete Repair Services

If you’re considering concrete raising, trust Slab Fix to assist you. We specialize in patio leveling, pool deck leveling, and other concrete leveling services using foam jacking. Our team ensures minimal disruption, long-term results, and environmentally friendly solutions.