Thermal Dynamics of Polyurethane Foam Expansion in Subsurface Soil Environments

Introduction

The use of polyurethane foam for soil stabilization has transformed the geotechnical and marine repair industries. As a lightweight yet high-strength solution, polyurethane provides a rapid, non-invasive, and long-lasting alternative to traditional cementitious methods. However, while most publications discuss foam chemistry, injection pressures, and expansion ratios, very few examine one of the most critical variables influencing performance — temperature.

The thermal dynamics of polyurethane reactions govern how effectively foam expands, cures, and bonds within subsurface environments. From Florida’s hot coastal soils to cooler inland regions, temperature and humidity fluctuations can alter foam density, reaction kinetics, and load-bearing performance.

This article explores the polyurethane thermal reaction mechanisms in soil stabilization applications, detailing how heat, moisture, and environmental conditions affect foam behavior and how SlabFix manages these factors to ensure uniform, reliable results under diverse site conditions.

1. Understanding the Chemical Kinetics of Polyurethane Foam Reactions

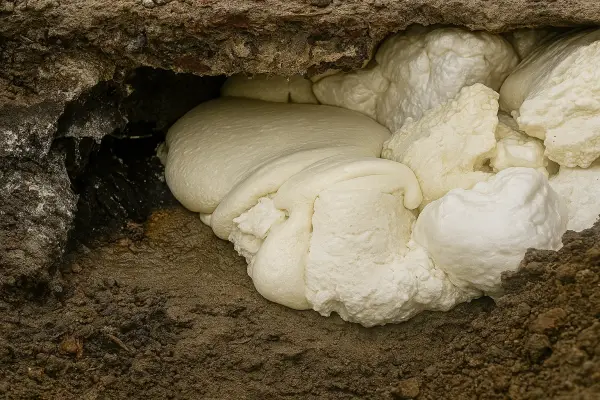

Polyurethane foam formation is an exothermic reaction between two components — an isocyanate (A-side) and a polyol (B-side). Upon mixing, these chemicals undergo polymerization, releasing heat as the foam expands and hardens.

In soil stabilization, this exothermic behavior is not just a chemical curiosity — it’s a key engineering factor. The temperature generated within the reaction zone affects viscosity, expansion rate, and final cell structure.

1.1 Reaction Stages and Heat Development

The polyurethane reaction follows three main stages:

Cream phase (initial mixing): Viscosity increases and bubbles begin forming.

Rise phase (expansion): Rapid gas generation (CO₂ or blowing agent vaporization) creates a cellular structure.

Cure phase (solidification): Heat accelerates polymer crosslinking, locking foam in place.

During the rise phase, internal temperatures can exceed 140°F (60°C), depending on formulation and soil confinement. If the surrounding soil is cool or moist, this heat dissipates unevenly, influencing foam uniformity and bonding quality.

1.2 Reaction Rate Dependence on Temperature

The reaction rate roughly doubles for every 10°C increase in temperature, following the Arrhenius principle. In field conditions:

Warm soil (>30°C) accelerates curing, potentially reducing expansion time and internal cell size.

Cold soil (<15°C) slows curing, allowing excess expansion but sometimes trapping gas pockets or causing incomplete bonding.

This makes thermal balance control essential for consistent results — particularly in deep or seasonally variable injection sites.

2. Soil Temperature Gradients and Their Influence on Expansion Uniformity

Subsurface temperatures vary with depth, season, and soil type. Florida’s coastal zones, for instance, often exhibit a 10–15°C gradient between shallow and deeper layers due to tidal and solar effects.

2.1 Vertical Temperature Stratification

In most soils:

Top 0–2 ft: High thermal fluctuation due to sunlight and surface water evaporation.

2–6 ft: Moderately stable zone with dampened daily variation.

>6 ft: Nearly constant year-round temperature (around 22–24°C in Florida).

When polyurethane is injected through multiple depth levels, this temperature stratification directly affects:

Reaction start time (cream time)

Viscosity buildup

Expansion rate

Foam density distribution

If the injection passes through varying thermal zones, the foam at warmer layers may expand faster than foam below, potentially creating density differentials and uneven load transfer.

2.2 Thermal Gradient Modeling

SlabFix utilizes field-calibrated models to estimate temperature effects before injection. By combining soil temperature logs and reaction time data, technicians predict optimal injection timing, spacing, and material volume to ensure consistent expansion throughout the treated depth.

3. Managing Injection Pressures in Varying Thermal Zones

Temperature doesn’t only influence reaction speed — it alters foam rheology, changing how it moves under pressure within the soil matrix.

3.1 Pressure–Viscosity Relationship

As polyurethane warms during reaction:

Viscosity decreases, allowing easier flow through fine-grained soils.

Expansion pressure increases due to faster gas evolution.

In cooler zones, the opposite occurs:

Higher viscosity slows flow and reduces lateral spread.

Expansion pressure decreases, increasing the risk of localized voids.

To counteract these dynamics, SlabFix technicians adjust injection pressure in real-time based on soil temperature readings.

For example:

In warm, sandy soils, lower initial pressure prevents overexpansion.

In cooler, dense clay, slightly higher pressure maintains adequate propagation.

3.2 Injection Control Technologies

Using digital pressure monitors and thermocouple feedback, SlabFix can maintain ideal conditions during field operations. This ensures the foam fills voids evenly and forms a continuous structural bond, regardless of temperature gradients.

4. Field Data: Comparing Summer and Winter Injection Results in Florida

Field testing across Florida’s coastal and inland sites has revealed distinct thermal influences on polyurethane behavior.

4.1 Summer Conditions (Average Soil Temp: 30–34°C)

Reaction speed: 30–40% faster

Foam rise pressure: ~20% higher due to increased gas production rate

Cure time: Reduced by 25–30%

Result: Denser foam with smaller, more uniform cell structure

However, overly high substrate temperatures can shorten working time, requiring careful control to prevent premature curing inside the injection hose or ports.

4.2 Winter Conditions (Average Soil Temp: 18–22°C)

Reaction speed: Slower by 35–45%

Foam rise pressure: Lower, leading to wider spread but less lift per volume

Cure time: Extended up to 3× longer

Result: Slightly larger cell structure, potential microvoid formation

SlabFix field protocols include warming material drums or slightly modifying component ratios to maintain optimal viscosity and expansion performance during colder months.

4.3 Performance Comparison

| Parameter | Summer Injection | Winter Injection | Controlled Adjustment by SlabFix |

|---|---|---|---|

| Average Reaction Time | 45 sec | 75 sec | Component temperature control |

| Average Expansion Pressure | 80 psi | 55 psi | Injection rate modulation |

| Final Foam Density | 3.5 lb/ft³ | 4.1 lb/ft³ | Controlled curing |

| Bonding Strength (to soil) | Excellent | Good | Improved via thermal conditioning |

5. Foam Cell Structure Behavior Under Fluctuating Subsurface Heat

One of the most direct thermal effects occurs at the microscopic cell structure level of polyurethane foam. Each cell’s size, shape, and wall thickness depend on the temperature and pressure during gas generation and curing.

5.1 Microstructural Impact

Higher temperatures accelerate gas expansion before polymer walls fully form, producing smaller, closed cells with high density and compressive strength.

Lower temperatures delay polymerization, allowing larger, irregular cell formation and potentially higher permeability.

Scanning Electron Microscope (SEM) studies of cured foam samples from Florida injection projects show:

Summer-injected foam had cell diameters averaging 0.35 mm

Winter-injected foam averaged 0.48 mm with 12% higher open-cell fraction

This microscopic variation explains measurable differences in field performance such as lift precision, load transfer efficiency, and long-term durability.

5.2 Structural Stability Under Thermal Cycling

In coastal regions, subsurface temperatures fluctuate daily due to tidal influence and shallow groundwater exchange. Polyurethane foam exhibits excellent thermal dimensional stability, with less than 1% volumetric change between 0°C and 50°C.

SlabFix selects formulations with optimized glass transition temperatures (Tg) and crosslinking density, ensuring the foam maintains strength even after thousands of thermal cycles.

6. SlabFix’s Approach to Achieving Consistent Density Through Controlled Curing

Achieving uniform density in polyurethane stabilization requires more than chemistry — it demands precise control of thermal and process parameters. SlabFix integrates proprietary injection protocols to ensure consistent performance in all environmental conditions.

6.1 Thermal Preconditioning

Before injection, both A-side and B-side components are thermally conditioned to a consistent temperature (typically 25–27°C). This preconditioning stabilizes the reaction rate, regardless of ambient or soil temperature.

6.2 Temperature-Responsive Injection Scheduling

SlabFix schedules injection sequences based on:

Real-time soil temperature profiles (from surface to target depth)

Local humidity and moisture content

Expected diurnal thermal shifts

By injecting during optimal thermal windows (typically morning or late afternoon in hot regions), SlabFix minimizes overreaction risks and ensures even expansion.

6.3 Adaptive Material Formulation

Depending on project conditions, SlabFix may select or fine-tune formulations with:

Variable catalyst concentrations to modify reaction rate

Additives that enhance thermal resistance

Modified blowing agents for improved performance under moisture-rich conditions

These controlled variables allow polyurethane to achieve predictable strength, lift, and waterproofing characteristics even under complex thermal scenarios.

7. Implications for Long-Term Soil Stabilization Performance

Thermal behavior during injection not only influences initial expansion but also affects long-term stability. Foam cured under controlled thermal conditions exhibits:

Higher compressive strength retention after cyclic wet-dry exposure

Improved adhesion to granular and cohesive soils

Reduced microcracking from thermal contraction or expansion stresses

Through years of field data, SlabFix has demonstrated that temperature-optimized injection protocols directly correlate with long-term performance in seawall stabilization, foundation underpinning, and void filling.

8. Case Insight: Florida Coastal Soil Stabilization

In a coastal stabilization project near Clearwater, Florida, SlabFix conducted a comparative study across seasonal temperature extremes.

Summer injection (32°C soil temperature):

Lift accuracy: ±2 mm

Injection efficiency: 94% material utilization

Curing time: 48 seconds

Winter injection (19°C soil temperature):

Lift accuracy: ±5 mm

Injection efficiency: 87% material utilization

Curing time: 78 seconds

By implementing thermal conditioning and adaptive catalyst adjustment, the winter-phase injection achieved nearly identical results to the summer phase, demonstrating the reliability of SlabFix’s thermal management methodology.

Conclusion

The thermal dynamics of polyurethane foam expansion represent a vital yet often overlooked aspect of soil stabilization engineering. From reaction kinetics to foam microstructure, temperature and humidity fundamentally dictate how polyurethane interacts with subsurface environments.

Through controlled curing, temperature management, and adaptive formulation, SlabFix has developed a scientifically grounded process that ensures uniform foam density, reliable expansion, and superior long-term stabilization across all Florida conditions.

As climate variability and construction challenges grow, mastering the polyurethane thermal reaction in soil stabilization will remain the cornerstone of achieving consistent, high-performance results — and SlabFix stands at the forefront of that innovation.